Part 1. The tender process and asphalt selection

Part 2. Pre-work baseline testing

Part 3. New Motorcycle Chicane at T3

Part 4. Re-profiling

Part 5. Earthworks for the New Motorcycle Chicane and new Kerbing

Part 6. Asphalting of the chicane commences

Part 7. Laying of the Asphalt on the Main Circuit commences

This report has been released in parts onto the new WASCC Facebook Page “WA Sporting Car Club Members and Officials”. If you are a Member or Official, please contact Georgina in the Office for access. The five parts below are now consolidated for folk not using the new Facebook facility

Part 1. The tender process and asphalt selection

A sub-committee comprising Glen Melling, Sean Supanz and Tim Riley (Chair) was formed. This got the project off to a solid start in May 2018.

Golder Associates were appointed as technical advisors and for QA/QC oversight during the works.

In order to keep our options open whilst technical merits of differing asphalt mixes were further assessed, submissions were requested for three combinations of stone / bitumen and polymer. Submissions were received from four pre-qualified companies.

The submissions were independently evaluated by Golder and WASCC. Both came to the same conclusion. Asphaltech, based in Malaga, was successful. It is perhaps no coincidence that Asphaltech undertook the last resurfacing work back in 2004. The same enthusiastic personnel are still there and were able to walk me to 3 test surfaces they placed on the short circuit interlink in 2003.

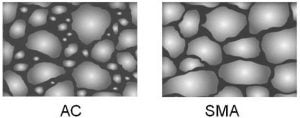

Putting aside polymer addition, the most critical question for the whole project was whether to depart from the more conventional (and previously used) 10mm Dense Graded Asphalt (DGA), and use newer technology 7mm Stone Mastic Asphalt (SMA) developed in Europe. For any bituminous mix, time is the enemy due to oxidation, UV damage and high shear forces on a race track.

DGA (aka AC) is typically about 10% cheaper (overall project cost) than SMA. Typically, DGA starts life very smooth, then develops more texture as stones are exposed. However, over time the finer material between the stones begins to fall out of the mix, a process called raveling. This is the issue with our surface right now. Actual contact area between tyre and the surface reduces, as the tyre travels over the tops of protruding stones. Under high shear loads in the latter life of the DGA surface, tyre wear can become a serious issue.

SMA has more of a single size mix of stone particles, bound by a higher % bitumen. For this reason, it is modestly more expensive. However, its strength is achieved more by stone on stone contact, relying less on the finer binding materials. The result has a number of advantages:

- Better early life grip in the wet.

- A more durable and consistent high grip surface over longer time frames.

- Likelihood of extended service life.

It is for these reasons that Main Roads, and increasingly Local Governments, are using SMA in areas of elevated traffic risk.

After consultations with leading experts from Germany, it was concluded that SMA was a logical choice for our circuit. The modest additional cost (circa 10% overall) was justified by expectations of lower tyre wear for members in the mid to long term, and likely longer service life of the new SMA surface. In November, Committee voted to use SMA for the resurface scheduled for the week of 14th January 2019.

Part 2. Pre-work baseline testing

Whilst the main re-surfacing work is scheduled week 14th January, some basic checks commenced in mid-December.

13th December 2018 Core drilling Core 1 on Start Finish Straight 80mm – all good

All six cores drilled confirmed 80-90mm tarmac over good limestone sub-base. Interestingly if you look at the track surface, you can see how we are currently driving across the top of 10mm stones, between which all the fines (look at core) have gone. This is the Start Finish Straight. The corners exhibit much worse raveling. You can also see two layers of previous asphalt in the core.

Next, we got an early start at 0600h on Friday 21 December as everyone was shutting down for Xmas / New Year. The survey vehicle was primarily there to assess the “bumpiness” of the existing surface. With luck and Asphaltech expertise, we hope the new track will present a smooth surface.

The survey gear can assess bumps with a wavelength of up to 50m which you would not even notice on a Freeway, but in a very stiffly sprung race car at very high speeds, you would. In an F1000, you sometimes feel like your eye-balls are shaking loose.

21st December Laser Survey Vehicle

Part 3. New Motorcycle Chicane at T3

Most will be aware of political complexity that has surrounded what we call “legacy issues” which were compounded by some very sad motorcycle related incidents. This effectively resulted in a ban on motorcycle activity.

In August 2018, we were able to re-initiate non-competitive bike activity through provider Track Action. https://wascc.com.au/motorcycle-activities-to-return-to-barbagallo/. WASCC committed significant funding to facilitate this return. I was able to inspect the “air-fence” at T3 up close today while the survey truck was doing laps. It is quite an impressive bit of kit.

The next step was obviously motorcycle racing which required further work.

Our GM Andrew Stachewicz energized and led this project, appointing Calibre Consultants to the task of designing a safer T3 for bikes.

Relax, the high speed Esses will remain for cars, but bikes will be slowed significantly by a right handed chicane as the track rises into T3, blending back into the main circuit on the right-hand side entry to T4.

The really good news is that Asphaltech were able to schedule this extra work into the course of the larger resurfacing project. This required many personnel to work during their traditional 2 week Christmas shutdown.

Design for the new Bike Chicane at T3

Part 4. Re-profiling

2009 got off to a good start on 2nd January, with 30mm old asphalt being removed, by a process known as profiling.

The process is highly efficient with the milled material transferred straight into tandem moving trucks, and stored locally for future works. The machine is operated by a driver, and a level controller who walks beside the machine.

After sweeping, a rough, fresh, clean surface is ready for asphalting.

2nd January 2019 Profiling (-30mm) Level control from side of machine

New Timing Loops (blue wires) will be retrofitted. Ready for new (additional) kerbing to be fitted

The last two photographs show where the old timing loops were intersected at one of 4 locations, and the remaining 50mm of old asphalt (after 30mm removed) overlying the original limestone sub-base. This track side edge is ready to receive additional kerbing off the normal racing line.

Part 5. Earthworks for the New Motorcycle Chicane and new Kerbing

27 December Survey for the new Bike Chicane 3rd January Raise elevation for new Bike Chicane

The new motorcycle chicane at T3 was surveyed as depicted above. The design required about 500 cubic meters of fill to raise the level and re-landscape the down slope area to avoid a large ‘drop-off’.

Next in was the crushed limestone which forms the sub-base for the chicane. The limestone is ‘engineered’ i.e. moisture conditioned and compacted. That is why the water tanker is present in the photograph below. Meanwhile, the down slope area was being re-landscaped.

4th January Limestone sub-base for chicane Re-landscape the infield to the new chicane

Part 6. Asphalting of the Chicane commences

Asphalting has started!!!

On Friday 11th January, the first of two asphalting machines arrived. It commenced laying 50mm DGA road-base over the limestone in the new motor-cycle chicane – now becoming known as the “bus stop”.

It was interesting to hear that ‘Scotty’ (the Asphaltech Supervisor in one of the photo’s below) had worked on the last resurfacing project back in 2003 – 2004.

A couple of interesting things strike me every time I visit the ongoing works:

* How new and well maintained all their equipment is

* The obvious friendliness of the workforce and their pride in being selected for the works at our race track.

On Monday 14th January, a tack coat will be placed onto the whole of the profiled Main Circuit, closely followed by 30mm SMA. This is what we race on for the first time on Saturday 2nd March.

Part 7. Laying of the asphalt on the main circuit commences

Here we go. Work started laying the SMA this morning. Our technical advisors (Golder Associates) are doing QA/QC and are reporting good results.

What’s happening here is a continuous tandem laying process where the paver (laying machine) pushes the truck ahead of it. The asphalt is discharged from the truck into the hopper at the front of the paver.

Then a second pair moves ‘en echelon’ so that the central joint is hot. The net result is a much stronger and neater joint.